Product Overview

Functional Definition

The LA‑10Q and LAZB‑10Q series are epoxy‑resin cast current transformers intended for indoor, through‑wall installation. Their primary conductor may be configured as a single turn, multiple turns or as a busbar to suit different switchgear layouts. Designed for 10 kV systems at 50 Hz or 60 Hz, the transformers provide galvanic isolation between primary and secondary circuits while delivering a secondary current of 5 A proportional to the measured primary current.

Key Ratings

| Item | Specification |

|---|---|

| System voltage class | 10 kV, indoor distribution equipment |

| Rated frequency | 50 Hz standard, 60 Hz on request |

| Primary current range | 5 A – 400 A (custom ranges available) |

| Rated secondary current | 5 A |

| Accuracy classes | 0.2/10P10, 0.5/10P10, 10P15 (others on request) |

| Rated burden per core | 10 VA (metering), 15 VA (protection) |

| Insulation level | 12/42/75 kV |

| Partial discharge | < 20 pC (at 1.2 Ur) |

| Applicable standards | GB 1208‑1997, IEC 60044‑1 |

Product Shows

Working Principle

The transformer operates on Faraday’s law of electromagnetic induction. The primary conductor passes through a toroidal magnetic core and produces a magnetic flux proportional to the primary current. The secondary winding, uniformly distributed around the core, senses the changing magnetic flux and induces an electromotive force that drives a secondary current in proportion to the primary current. This arrangement provides accurate measurement and electrical isolation between the primary power circuit and secondary instrumentation or protection devices.

System Application Position

- Medium‑voltage distribution: 10 kV switchgear, metal‑clad panels and cable termination cabinets.

- Energy metering: Revenue‑grade measurement and power quality monitoring.

- Protection circuits: Over‑current, differential and distance protection schemes in substations and industrial plants.

- SCADA integration: Supervisory control and data acquisition systems requiring isolated current feedback.

Structural Overview

LA‑10Q and LAZB‑10Q transformers feature a through‑wall (wall‑mount) structure. The primary conductor is either a single turn, multiple‑turn winding or an integrated busbar passing through the cast resin body. The epoxy resin encapsulation integrates the primary winding, secondary winding and magnetic core into a single component, delivering excellent insulation, moisture resistance and mechanical strength. High creepage distance and robust environmental sealing make these transformers suitable for heavy humidity and light pollution conditions.

Model Designation

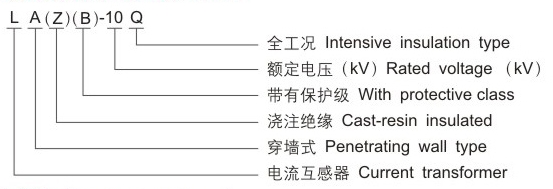

Model designation

L = Current transformer (CT)

A = Penetrating wall type

(Z) = Cast-resin insulated (optional)

(B) = With protective class (optional)

-10 = Rated voltage: 10 kV

Q = Intensive insulation type / all-condition insulation type

The naming convention distinguishes between the LA‑10Q and LAZB‑10Q variants. Both share identical electrical characteristics; the difference lies in mechanical configuration and installation details:

- LA‑10Q: (Above 400A ) Standard through‑wall, epoxy‑resin current transformer.

- LAZ-10Q: Same as above + cast-resin insulation

- LAZB‑10Q: Same as above + cast-resin insulation + protective class, Enhanced creepage design with optional multiple turn or busbar primary, suitable for applications where higher creepage distance is required.

Variant Differences

Both variants are electrically equivalent when ordered with the same ratio, accuracy class and burden. LAZB‑10Q offers an extended creepage distance and mechanical adaptations for specific switchgear layouts. The appropriate model should be selected based on the switchgear’s through‑wall opening and environmental requirements.

Service Conditions

- Altitude: ≤ 1000 m above sea level; higher altitudes require consultation.

- Ambient temperature: −5 °C to +40 °C.

- Relative humidity: ≤ 85 % at 20 °C.

- Environment: Free from corrosive gases, heavy pollution or chemical contamination.

- Pollution level: Suitable for high humidity and light pollution environments.

- Vibration resistance: Properly mounted units withstand normal shock and vibration experienced in switchgear operation.

Construction

Construction Design

- Structure: Through‑wall, support‑type arrangement for indoor switchgear.

- Insulation: Fully enclosed epoxy resin casting for superior insulation and moisture protection.

- Core: High‑grade silicon steel ring‑type core for reduced magnetizing losses.

- System: Integrated primary and secondary assembly ensures uniform insulation and mechanical stability.

Windings & Terminal Marking

- Primary terminals (P1, P2): Busbar or conductor ends extend through the wall bushing; orientation marks ensure correct connection.

- Secondary terminals (S1, S2): Exposed terminals located at the base for convenient wiring and maintenance.

- Polarity: Current direction is referenced from P1 to P2; connect secondary circuits accordingly to maintain polarity.

- Core material: High‑quality silicon steel improves measurement accuracy and reduces excitation current.

Technical Data

The technical data below provide guidance for selecting LA‑10Q and LAZB‑10Q current transformers. Actual nameplate values and factory test reports shall prevail. Parameters can be customized to meet project‑specific requirements.

Data Reference

| Rated primary current (A) |

Accuracy class combination |

Rated output (VA) |

Thermal current Ith (kA/1 s) |

Dynamic current Idyn (kA) |

|---|---|---|---|---|

| 5–100 | 0.2 / 10P10 or 0.5 / 10P10 | 10 / 15 | 0.5 | 0.8 |

| 10 / 5 | 0.2 / 10P10 | 10 / 15 | 0.9 | 1.6 |

| 20 / 5 | 0.5 / 10P10 | 10 / 15 | 1.8 | 3.2 |

| 50 / 5 | 10P15 | 15 | 4.5 | 8.0 |

| 100 / 5 | 10P15 | 15 | 9.0 | 16.0 |

| 200 / 5 | 10P15 | 15 | 18.0 | 26.0 |

| 400 / 5 | 10P15 | 15 | 30.0 | 54.0 |

Application Scenarios

Primary Applications

- Medium‑voltage switchgear: Ring main units, metal‑clad switchgear, circuit breaker panels and motor control centres.

- Energy metering: Commercial and industrial power metering, power quality monitoring and revenue billing.

- Protection relay systems: Over‑current, differential, feeder and motor protection schemes.

- Industrial power distribution: Monitoring and protection of manufacturing lines and process automation equipment.

Installation Environments

| Environment Type | Characteristics | Engineering Considerations |

|---|---|---|

| Indoor substations | Controlled environment, minimal contamination | Standard configuration suitable under normal service conditions |

| Industrial plants | Possible dust, vibration and chemical exposure | Specify vibration and contamination level; confirm installation clearances |

| Coastal / high humidity | High humidity and salt fog; risk of condensation | Specify humidity control and ensure creepage distance is adequate |

| High dust environments | Dust accumulation and increased surface contamination risk | Provide regular cleaning plan and ensure sufficient clearance for insulation |

| High altitude sites | Reduced air density affecting insulation performance | Specify altitude in order documentation for insulation coordination verification |

Standards & Normative References

| Standard | Title | Application |

|---|---|---|

| IEC 60044‑1 | Instrument Transformers – Current Transformers | Base design and performance requirements |

| GB 1208‑1997 | Current Transformers | National standard equivalent to IEC 60044‑1 |

| IEC 61869‑1 / IEC 61869‑2 | Instrument Transformers – General and Current Transformer Requirements | Optional compliance where specified |

| GB/T 20840.1 / GB/T 20840.2 | Instrument Transformers – General and Current Transformer Requirements | Applicable national standards aligning with IEC 61869 |

Factory Test Compliance

- Routine tests: Polarity verification, ratio and accuracy tests per specified class and burden.

- Dielectric tests: Power frequency and lightning impulse tests to verify insulation coordination.

- Partial discharge: Tested according to standard requirements when specified.

- Visual and dimensional inspection: Marking and workmanship checks to ensure conformity.

- Type and special tests: Performed according to project or tender specifications.

Installation & Dimensions

- Outline drawings and mounting details are provided upon request.

- The transformer shall be securely mounted using the designated fixing holes and brackets.

- Primary conductor connection may be made via busbar or bolted terminals, depending on the selected variant.

- Maintain adequate electrical clearance and creepage distance for insulation and heat dissipation.

Safety Notes

- Never leave the secondary circuit open while the transformer is energized; dangerous voltage may appear on the secondary terminals.

- Before maintenance or testing, short‑circuit and ground the secondary circuit in accordance with applicable safety regulations.

- Ensure correct polarity and proper grounding of one point in the secondary circuit.

- All installation and maintenance activities shall comply with local electrical safety standards.

Ordering Information

When ordering LA‑10Q or LAZB‑10Q current transformers, specify the following parameters to ensure the correct configuration:

- Rated primary current / transformation ratio.

- Application and accuracy requirements (e.g., 0.2 / 10P10).

- Rated burden (VA) for metering and protection cores.

- Short‑circuit withstand requirements (thermal and dynamic currents).

- Mechanical variant (LA‑10Q or LAZB‑10Q) and installation constraints.

- Any special requirements: insulation level, partial discharge limit, terminal arrangement, documentation language or certificates.

How to select:

- Determine the rated primary current based on feeder load and expected operating range.

- Select the required accuracy classes for metering and protection functions.

- Confirm the rated burden per secondary circuit, taking into account connected instruments and cable losses.

- Verify the short‑circuit withstand capability against the system fault level.

- Consult the manufacturer for any special configurations or environmental considerations.

FAQs

Q1: What applications are supported?

These transformers are suitable for current measurement, energy metering and relay protection in 10 kV industrial and power distribution systems.

Q2: What are the benefits of epoxy resin encapsulation?

Epoxy resin provides excellent insulation, moisture and pollution resistance, enabling the transformer to operate reliably in harsh environments and extend service life.

Q3: Can the transformers be customized?

Yes. Primary current ratio, accuracy class combination, output capacity and mechanical configuration can be tailored to project requirements.

Q4: What safety measures should be observed during installation?

Ensure correct connection of primary and secondary circuits, reliable grounding, and never operate with an open secondary circuit.

Q5: What standards do these transformers comply with?

They are designed in accordance with IEC 60044‑1 and GB 1208‑1997 and may comply with IEC 61869 and related national standards upon request.

Q6: What is the maximum supported current?

Standard configurations support primary currents up to 400 A with thermal current withstand of 30 kA and dynamic current withstand up to 54 kA.