Product Overview

Functional Definition

The LJWD-10/12 Oil-Immersed Current Transformers are precision oil-immersed electromagnetic instruments designed for accurate current measurement, energy metering, and relay protection applications in medium-voltage AC power systems. These outdoor-rated transformers utilize electromagnetic induction principles combined with mineral oil insulation and cooling to provide galvanically isolated secondary current signals proportional to primary current, featuring steel-tank construction for enhanced environmental protection and thermal management.

Key Ratings Snapshot

| Item | Specification (per order / nameplate) |

|---|---|

| System voltage class | 10 kV / 12 kV class (outdoor distribution applications) |

| Installation environment | Indoor and outdoor installation |

| Cooling method | Oil-immersed natural cooling (self-cooled) |

| Rated frequency | 50 Hz (60 Hz available upon request) |

| Rated secondary current | 5 A standard |

| Accuracy classes | 0.2 (metering), 0.5 (metering), 3 / D (protection) |

| Rated burden | Per core/winding as specified (VA) |

| Continuous thermal rating | 120% of rated primary current (continuous operation) |

| Short-time thermal current (Ith) | Up to 30 kA (1 s) |

| Rated dynamic current (Idyn) | Up to 50 kA (peak) |

| Thermal stability coefficient | 187.5× rated primary current |

| Insulation system | Mineral oil immersed with steel tank enclosure |

| Applicable standards | GB 1208-1997; IEC 61869-1 / IEC 61869-2 |

| Configuration options | Single/dual ratio with single/dual secondary windings |

Product Shows

Working Principle

Operating on Faraday’s law of electromagnetic induction, the LJWD-10/12 transformer features a toroidal magnetic core with primary conductor passing through the aperture and secondary windings wound around the core. The magnetic flux generated by primary current induces proportional voltage in the secondary winding, delivering standardized output current through connected burden. The oil-immersed design provides superior insulation coordination and thermal dissipation, enabling higher continuous current ratings and enhanced short-circuit withstand capability compared to dry-type transformers.

System Application Position

- Medium Voltage Distribution: 10-12 kV outdoor substations and distribution systems

- Energy Metering: Revenue-grade electricity measurement in urban and rural power grids

- Protection Circuits: Overcurrent, earth fault, and directional protection schemes

- Industrial Substations: Plant distribution systems requiring outdoor-rated equipment

- SCADA Integration: Remote monitoring and control systems in distribution automation

Structural Form Overview

Steel-tank oil-immersed construction with single-phase self-cooled design ensures superior insulation performance, environmental protection, and thermal management. The outdoor-rated enclosure features weather-resistant finish, oil filling valve, and rain/snow protection cap. Internal diaphragm design isolates insulating oil from atmospheric air, reducing oxidation and extending service life. The compact mounting configuration provides versatile installation options while maintaining excellent electrical clearance requirements.

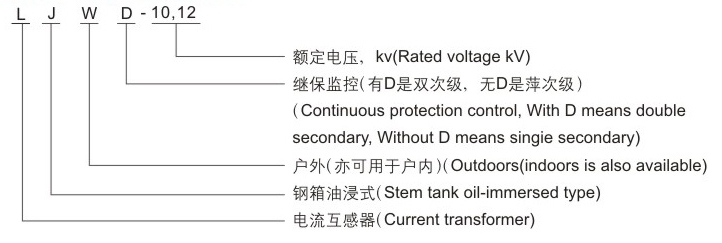

Model Designation

Model Code Explanation

- L — Current transformer (CT)

- J — Oil-immersed insulation system

- W — Outdoor installation type (weather-resistant)

- D — Single-phase design

- 10 / 12 — Voltage class (kV)

Configuration Variants

LJWD-10 and LJWD-12 share identical construction principles with voltage-dependent insulation levels. Available configurations include:

- Single ratio + single secondary winding (measurement or protection)

- Single ratio + dual secondary windings (combined metering and protection)

- Dual ratio + single secondary winding (flexible primary range)

- Dual ratio + dual secondary windings (maximum flexibility)

Service Conditions

The LJWD-10/12 series current transformers are designed for outdoor and indoor operation under normal service conditions in medium-voltage power systems.

| Installation environment: | Indoor and outdoor installation (IP-rated enclosure) |

|---|---|

| Altitude: | Not exceeding 2000 m above sea level (4000 m capability available) |

| Ambient temperature: | −25 °C to +40 °C |

| Relative humidity: | ≤ 95% (no condensation) |

| Pollution degree: | Grade II (light to medium industrial pollution) |

| Environmental conditions: | Free from corrosive gases or vapors; free from explosive or flammable media; no severe vibration, mechanical shock, or impact |

Construction

Construction Design

- Structure: Single-phase outdoor type with steel-tank enclosure

- Insulation: Mineral oil-immersed with diaphragm breathing system

- Core: Ring-type magnetic core with optimized silicon steel laminations

- Tank design: Welded steel construction with weather-resistant coating

- Sealing system: Oil filling valve with rain/snow protection cap

- Cooling: Natural oil circulation (self-cooled) for optimal thermal management

The advanced vacuum oil-filling and oil-impregnation process ensures bubble-free insulation, enhanced dielectric strength, and superior cooling performance. Internal diaphragm isolates insulating oil from atmospheric moisture, preventing oxidation and maintaining long-term insulation integrity.

Thermal Performance

The LJWD-10/12 features exceptional thermal stability with a thermal stability coefficient of 187.5× rated primary current, ensuring reliable operation under extreme fault conditions. The oil-immersed design provides superior heat dissipation compared to dry-type transformers, enabling continuous operation at 120% rated current without derating.

Windings & Terminal Marking

- Primary terminals: P1 / P2 (bushing-type connection)

- Secondary terminals (Group 1): 1S1 / 1S2

- Secondary terminals (Group 2): 2S1 / 2S2 (where dual winding specified)

Terminal markings follow standard CT polarity conventions per IEC 61869-2 and GB 1208-1997. Under normal operating conditions, the reference current direction is defined from P1 to P2. Correct terminal identification shall be observed to ensure metering and protection performance.

Technical Data

This section provides selection-oriented technical data for the LJWD-10/12 series outdoor, oil-immersed current transformer used in 10-12 kV class AC systems (50 Hz). Data shown below is intended for preliminary selection of transformation ratio, accuracy class combinations, rated burdens, and short-circuit withstand capability.

Definitions: Accuracy class indicates metering (0.2, 0.5) or protection (3, D) application. Rated output (VA) is specified per secondary core. Ith is the rated short-time thermal current (typically 1 s). Idyn is the rated dynamic current (peak). Thermal stability coefficient represents the multiple of rated current the transformer can withstand thermally.

Technical Specifications

| Rated Primary Current (A) |

Secondary Windings |

Accuracy Class | Rated Output (VA) |

Short-time Thermal Current (Ith, 1s) |

Rated Dynamic Current (Idyn) |

|---|---|---|---|---|---|

| 5 – 50 | Single or Dual | 0.2 / 0.5 / 3 / D | 5 – 15 | 15 kA | 37.5 kA |

| 75 – 100 | Single or Dual | 0.2 / 0.5 / 3 / D | 5 – 20 | 20 kA | 50 kA |

| 150 – 300 | Single or Dual | 0.2 / 0.5 / 3 / D | 10 – 30 | 25 kA | 62.5 kA |

| 400 – 600 | Single or Dual | 0.2 / 0.5 / 3 / D | 15 – 30 | 30 kA | 75 kA |

| 800 – 1000 | Single or Dual | 0.2 / 0.5 / 3 / D | 20 – 40 | 30 kA | 75 kA |

| 1200 – 1500 | Single or Dual | 0.5 / 3 / D | 30 – 50 | 30 kA | 75 kA |

Standards & Normative References

| Standard | Title | Application |

|---|---|---|

| GB 1208-1997 | Current Transformers | Primary national standard for CT requirements |

| IEC 61869-1 | Instrument Transformers – Part 1: General Requirements | International general requirements |

| IEC 61869-2 | Instrument Transformers – Part 2: Additional Requirements for Current Transformers | International CT-specific requirements |

| GB/T 20840.1 | Instrument Transformers – Part 1: General Requirements | National standard (aligned with IEC 61869 framework) |

| GB/T 20840.2 | Instrument Transformers – Part 2: Current Transformers | National CT requirements (aligned with IEC 61869-2) |

| DL/T 866 | Technical Specifications for Current Transformers | Power industry technical specification |

| IEEE C57.13 | Standard Requirements for Instrument Transformers | Optional (North America project reference) |

| IEC 60085 | Electrical Insulation – Thermal Evaluation | Insulation thermal class evaluation reference |

Factory Testing Compliance

- Routine tests per GB 1208-1997 and IEC 61869-2 (including polarity/marking, ratio verification, accuracy verification per specified class and burden)

- Dielectric tests per insulation coordination requirements and applicable standard (power frequency withstand voltage, impulse voltage)

- Oil quality tests including breakdown voltage and moisture content verification

- Temperature rise test at rated continuous thermal current (1.2× In)

- Short-circuit test for thermal and dynamic withstand capability verification

- Visual and dimensional inspection including marking, sealing integrity, and workmanship conformity

- Type and special tests as required by the project specification

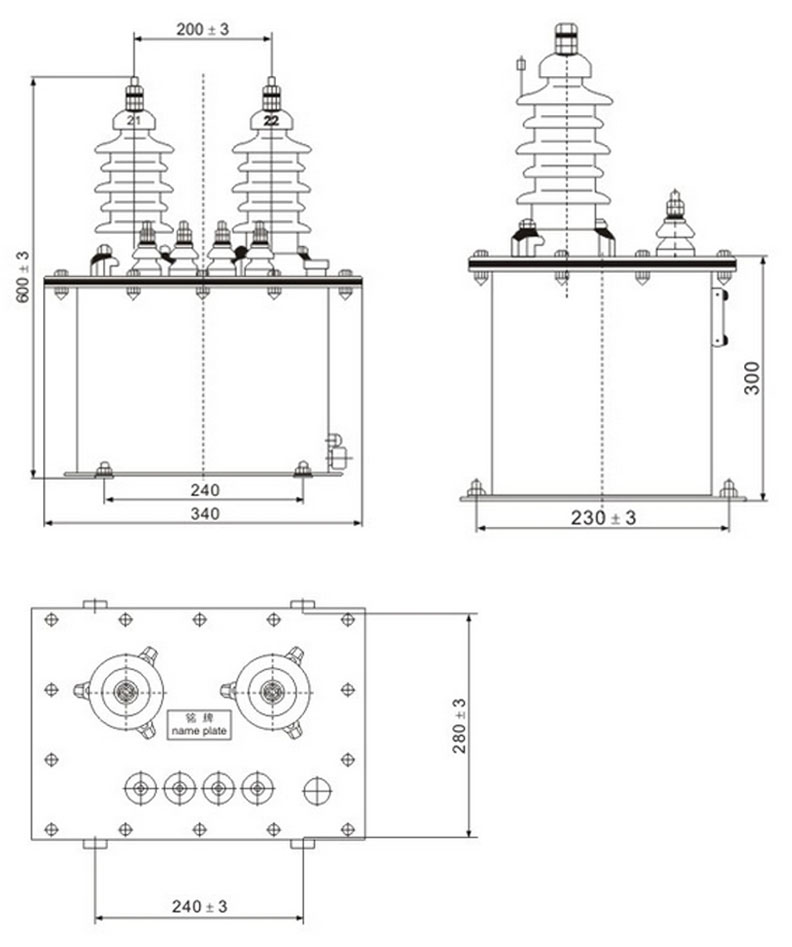

Installation & Dimensions

- Outline dimensions and mounting details are provided in the dimensional drawings.

- The transformer shall be securely mounted using the designated fixing holes in accordance with installation drawings.

- Primary conductor connection may be made via busbar through-type or bolted terminals, depending on system configuration.

- Adequate clearance shall be maintained for insulation coordination, heat dissipation, maintenance access, and oil level inspection.

- Oil filling valve shall be accessible for periodic oil quality checks and oil topping when required.

- Tank grounding shall be verified per local electrical safety codes.

Outline

LJW-10 and LJWD-12 Installation Outline Dimensions

Safety & Maintenance Notes

- Secondary circuit must never be left open when the transformer is energized, as dangerous high voltage may appear across the secondary terminals.

- During inspection or maintenance, the secondary circuit shall be short-circuited before disconnecting any instruments or protective relays.

- One point of the secondary circuit should be reliably grounded in accordance with applicable standards (typically S2 terminal).

- Periodic inspection of oil level, oil quality, and tank sealing integrity is required per maintenance schedule.

- Oil dielectric strength testing recommended every 3-5 years or per utility requirements.

- Secondary terminal tightness shall be verified during scheduled maintenance intervals.

- All installation and maintenance work shall comply with local electrical safety regulations and utility standards.

Ordering Information

When placing an order, the required configuration shall be specified according to the local grid requirements, applicable standards, and project technical specification. The following parameters shall be clearly stated for technical confirmation and production release:

- Voltage class: 10 kV or 12 kV

- Rated primary current / transformation ratio (e.g., 100/5, 200/5, dual ratio if required)

- Rated secondary current (5 A standard, 1 A upon request)

- Number of secondary windings (single or dual)

- Application and accuracy requirements for each winding (metering: 0.2, 0.5; protection: 3, D)

- Rated burden (VA) for each secondary core/winding

- Short-circuit withstand requirements: Ith (1 s) and Idyn (peak)

- Environmental conditions: Altitude, pollution degree, temperature range if non-standard

- Special requirements: Dual ratio configuration, extended temperature range, enhanced seismic rating

Selection Guide

Step 1: Determine rated primary current (Ip) based on feeder/load rating and expected operating range. Consider future load growth.

Step 2: Select metering and/or protection accuracy requirements:

- Class 0.2 for revenue metering (high accuracy)

- Class 0.5 for operational metering

- Class 3 or D for overcurrent protection

Step 3: Confirm rated burden (VA) for each secondary circuit based on connected meters/relays and wiring losses. Include safety margin of 25-50%.

Step 4: Verify short-circuit withstand capability (Ith/Idyn) against the system prospective short-circuit current. Consult utility fault study.

Step 5: Specify dual winding configuration if separate metering and protection cores required (recommended for revenue metering applications).